- Products

- Service

- Expertise

- References

- fischer group

- Contact

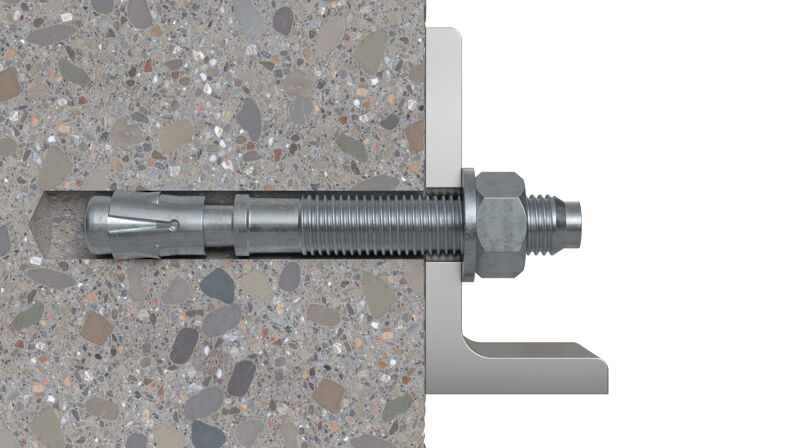

| ETA-approval | |

| Drill diameter ( d0 ) | 10 mm |

| Min. drill hole depth for through fixings ( h2 ) | 78 mm |

| Anchor length ( l ) | 85 mm |

| Max. usable length hef,stand./hef,min. ( tfix ) | 10 / 20 mm |

| Thread ( ø x length ) | M10 x 46 mm |

| Width across nut | 17 mm |

| Packaging | Folding box |

| Amount | 50 pcs. |

| GTIN (EAN-Code) | 4006209408278 |